If you own a scroll saw, you may have noticed that the amount of vibration from them can be quite excessive.

This vibration doesn’t mean that anything is wrong, though; it is how the scroll saw works.

Why do scroll saws vibrate so much? Scroll saws vibrate because of their reciprocating blade movement. Since the blade movement is constant, the vibrations are constant, as well.

This incessant vibration may be an annoying aspect of the scroll saw, but it is one with possible solutions and explanations.

Read on to find out why your scroll saw vibrates so much and what you can do to lessen the vibrations.

Why do Scroll Saws Vibrate So Much?

To understand what is causing the vibration on your scroll saw, you must first have a general understanding of what a scroll saw is and how it works.

Scroll saws are small electric saws with a small, thin blade. They are used in curves and edge work with wood, plastic, and metal by rotating the saw while you cut.

The blade of a scroll saw moves up and down rapidly, moving anywhere from 500 to almost 2000 times in a minute.

The main cause of the vibration is this fast movement of the blade. But if the blade were to slow down, it would not be able to cut through the material as effectively.

The vibration also reduces the amount of impact the saw has on your hands as you work.

The movement of the blade causes intense vibrations and can usually be felt through the table or the object you are cutting.

If you are feeling a greater amount of vibration from your scroll saw than normal, there may be something that you can do to correct the vibration level.

How to Correct My Scroll Saw if I Have Too Much Vibration

The ability of the blade to vibrate properly is what makes a scroll saw work correctly; however, sometimes you may notice that your saw is vibrating more than it should be.

If you find that your scroll saw seems to be vibrating too much, here are some tips to help:

Sturdy its Surroundings

When you work with your scroll saw, it is attached to a table or bench.

You want to make sure that the surface you are working on is well bolted to the saw so that it doesn’t start moving while you are working.

This will assist in steadying your saw’s movements as a heavier, stronger surface will vibrate less as opposed to one that was wobbly, to begin with.

Check the Counterweight

Scroll saws come with a device called a counterweight that is used to either minimize or get rid of the vibrations.

It could be possible that the counterweight is either not properly balanced or is missing from your saw.

If this is why your saw is vibrating too much, you should add some weight to balance it out.

You can use sandbags, steel weights, lead, or concrete as extra weights. Adding weight shifts most of the smaller vibrations away from where you are cutting.

The weight needs to be placed near the base part of your scroll saw. Watch to make sure that the weights don’t interfere with the saw’s cutting.

Purchase a Shock Absorber

You can purchase rubber shock absorbers for either the machine, the table, or the bench’s legs.

It’s a type of soft material like a mouse pad and is a quarter of an inch thick.

You can glue these under the legs of your bench or table or have them in between bolts on your scroll saw.

Inspect the Saw

Another thing that can cause your scroll saw to vibrate more than usual is if it’s initial set up was done incorrectly.

If you’ve checked everything else and you have not found a solution to the issue, inspect the scroll saw to make sure it was put together correctly.

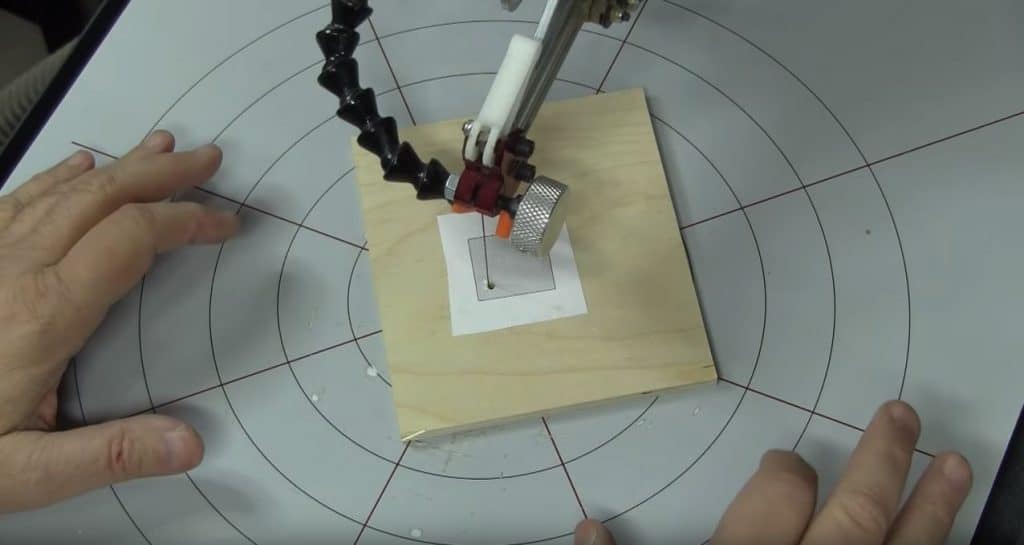

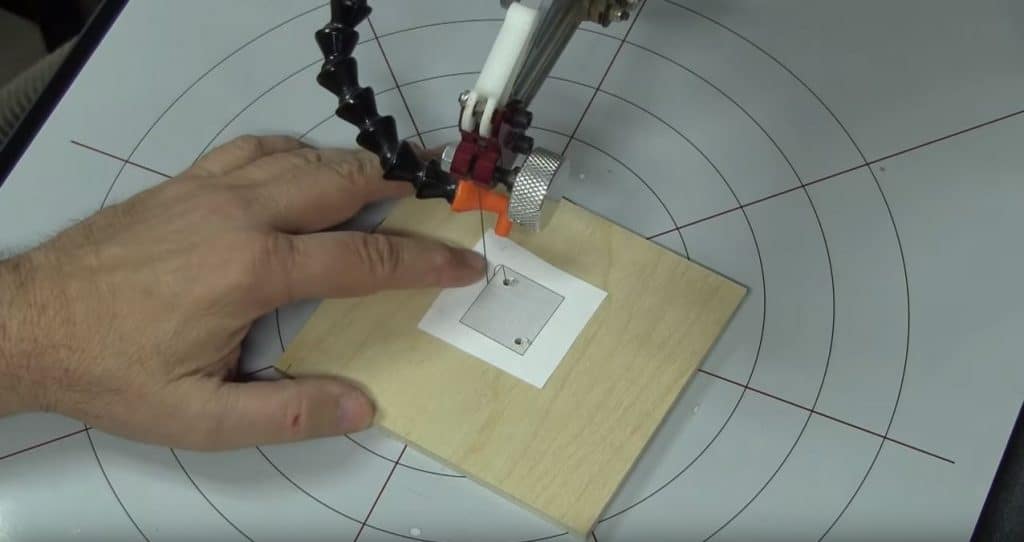

The way to do this is to turn it on and look at the blade of your saw as you do a practice cut through any of your usual materials.

You are watching to see if the blade is going up and down and front to back.

If the blade is moving correctly, it will look like nothing more than a black line in your eyes; if your blade is a blurry or more circular shape, then you need to adjust either the tension or the saw arm.

If your blade is looser than it’s supposed to be, the arms of your scroll saw will be out of sync.

You might even hear a noise made every time your blade goes upward.

Below is a short video of a smooth vibration of a scroll saw:

Fixing this depends on your brand of the saw, so referring to the manual or looking up the manufacturer’s tension settings is recommended.

Related Article: How tight scroll saw blade should be, tools can perform amazingly with the right tweak!

Am I The Cause of My Scroll Saw’s Excessive Vibration?

While there are technical reasons that can cause your scroll saw to vibrate too much, excessive vibration can also be caused by user error.

The reason your scroll saw is vibrating so much maybe because you are using it incorrectly. Misuse is prominent in people using a scroll saw for the first time.

A certain type of technique is required when using scroll saws, and it is not the same as other saws.

Here are some tips on how to use your scroll saw correctly:

Correct Grasp

First, make sure that the piece you’re working on is held firmly against the table at the starting point.

Proper Pressure

Next, apply steady forward pressure to the blade to move it through the material.

Make sure that you are not forcing the blade. Letting your blade do all the work instead of pushing your way through is the proper way to use a scroll saw.

Push straight onto the saw; if you turn it too much to the side, you can make the teeth of the blade chatter.

The only time you want to push the saw sideways is when you make edges or curves.

Speed Switch

Your machine will usually come equipped with various speed settings to adjust to the thickness, material, hardness, and lamination of your piece.

If your speed is set too low, the teeth of the blade will grab onto what you are cutting, and this will force you to have to hold it down harder, which can be uncomfortable and cause unnecessary vibration.

Does Brand Matter?

Some find that the brand or price of a scroll saw does make a difference in the vibration level.

Cheaper scroll saws will vibrate more than the pricier ones, so upgrading your saw can be a way to fix the vibration issue.

Here are our top 3 recommended Scroll Saws:

| DEWALT DW788 Scroll Saw | This saw is made of cast iron, so it has the structural support needed to reduce vibrations. Its double parallel arms also claim to reduce the vibrations of the saw. |

| WEN 3921 Scroll Saw | The cast iron in this saw prevents both vibration and walking during use. It also has a foot clamp to help with support during projects. |

| DREMEL MS20-01 Scroll Saw | This saw includes an auto-tension feature, so you don’t have to worry about the blade’s adjustments. It has a variety of speeds, so it is easy to find the best speed for your material. It also includes a clamp base for the sturdiness needed to reduce vibration. |

Conclusion

Scroll saws vibrate because of the constant motion of their blades. However, there are times that the saws vibrate excessively.

When this happens, utilize the steps in this article to figure out the issue, so you can get back to doing beautiful projects!