If you have any experience with or knowledge about woodworking, then you know that there are many different types of saws, each with their pros and cons.

Today we are focused on one of the most versatile of all saws: the band saw.

What do band saws do? Band saws can do many exciting things, including woodworking, ripping lumber, and even cutting metals. You can make incredible curves and scrolls with a band saw too. On top of that, you can resaw and reset edges and faces of the board. And you can make veneer, bent laminations, and small logs.

Today we’re going to discuss in more detail everything that you can do with a band saw.

And if you’re in the market for a new machine, then we will give you several suggestions. But before we get to the saws, let’s go over some of the band saw basics.

What Is a Band Saw?

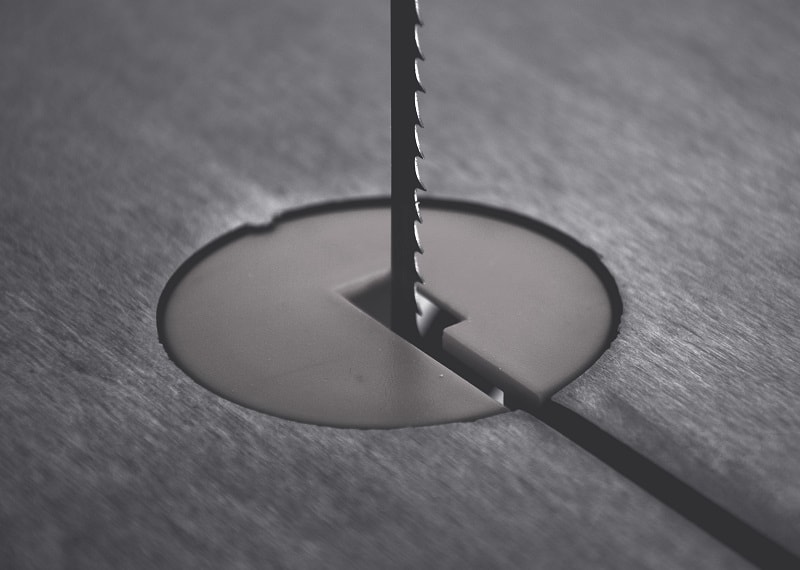

A band saw, sometimes written as a bandsaw, is a power saw that uses a long blade loop stretched between two wheels.

You can think of the blade like a ribbon that continually rotates along with the wheels.

Band saws are most often used for woodworking. However, you can also use them for lumbering and metalworking.

The main advantage of using a band saw is that you can do the highly uniform cutting. This is thanks to the evenly distributed tooth load.

A bandsaw can easily cut curved or irregular shapes. It works a lot like a jigsaw, but it allows you to have more control.

Band saws aren’t the only saws that can make intricate cuts. But they are arguably the easiest to use.

Only a small part of the blade loop shows in the cutting area.

However, most band saws allow you to make adjustments to expose more of the blade. This is helpful if you’re working on larger pieces of wood.

Because band saws feature small-sized blades, you can use them to make detailed, intricate cuts.

With these machines, the blade loop comes up through the center of the table on the saw.

The table is where you place the wood before you move it to meet the blade.

Band saws also let you adjust the speed, and they let you make mitered and angled cuts, depending on the table surface of the saw.

There are several different types and sizes of band saws. We’ll go over some of them in a minute.

To learn more about the basics of band saws, watch this great video:

The History of Band Saws

The band saw’s history goes back a long way. And there were many different versions of this saw before the machine that we have now.

Notable dates in the history of band saws include:

- The first British patent for a band saw went to William Newberry in 1809.

- The first American patent for a band saw went to Benjamin Barker in 1836.

- A patent for the modern blade of the saw went to Anne Paulin Crepin in 1846.

- In 1858 improvements in the mounting of the saws were made by Henry Wilson.

- Wide commercial use of band saws began around 1878 with the Cincinnati-based J. A. Fay and Company.

- In 1908 a foot power band saw was introduced by the Silver Manufacturing Company in Salem, Ohio.

The earliest versions of band saws weren’t at all practical.

The problems that they faced were because the technology had not yet been invented to create durable, lasting blades.

Because the blade loops are continually bending and flexing around the wheels, the pressure caused the blades to break most of the time.

So it became a priority to improve the blades. Once a new welding method using new steel alloys and advanced tempering techniques was developed, everything changed for the band saw.

The new functional blades instantly made the machine more feasible.

Since the 1800s, there have been significant improvements made to the band saw.

Once the machine was commercially produced, it quickly became popular among builders and lumberyards.

You can read more about the interesting history of bandsaws here.

What’s the Difference Between a Band Saw and a Scroll Saw?

In the woodworking world, you will often find people debating about choosing between a band saw and a scroll saw.

It can be a tough decision because both of these saws are excellent at handling curved cuts.

They can both make super accurate scrolling cuts that you can use for numerous applications.

The two saws are similar because of what they can do. But there are some significant differences too.

The main one has to do with the blades and how they move.

They have very different blades

Band saws use blades that are in a continuous loop around the saw’s wheels. With band saws, the blade cutting direction is always downward.

This feature allows the band saw to handle more substantial work, like cutting down large pieces of lumber.

Scroll saws look similar to band saws, but they differ in how they work.

With a scroll saw, the blade moves up and down reciprocating rapidly. Scroll saws work more similarly to a jigsaw than a band saw.

One benefit of the scroll saw is that it allows you to make cuts inside of the wood. That means that scroll saws don’t require an entry point cut.

For this application, you would first drill a hole in the wood. Next, you would thread the blade up through the hole. Then, you can begin your cutting from there.

The differences in the blades change the way the saws cut. The up and down movement of the scroll saw lets you make more precise cuts.

Scroll saws allow for tighter curves. They also leave you with a smoother surface after the cut. Often the pieces don’t need any sanding at all.

Band saws are king when it comes to versatility

While it’s true that scroll saws offer some advantages when it comes to precision, they can’t compete with the band saw when it comes to versatility. It’s not even close.

One cool thing about the band saw is that it can make cuts nearly as precise as a scroll saw while also giving you the ability to tackle more substantial cutting tasks. Band saws can also handle harder materials.

You can use a band saw to do things like cutting irregular and curved pieces, plastics, pipes, and larger pieces of lumber.

Band saws will help you with ripping, resawing, and breaking down boards to smaller pieces.

While the band saw offers much more versatility than a scroll saw, we believe that both are useful tools to have.

However, if you have to choose just one of them, we recommend the band saw.

Types of Band Saws

As we’ve discussed, band saws are mainly used for cutting wood. But they can also be used to cut metal.

There aren’t two different machines for cutting wood or metal. Either way, you use the same saw, it’s just the blade that is different.

But with that said, there are some different types of band saws available on the market today.

Horizontal

These band saws are most often used for cutting pieces at right angles or miter angles.

Horizontal band saws are generally floor mounted. They are used for making basic cuts with different materials.

With this type of band saw, the cutting position is horizontal. That means that the idler and drive wheels are positioned lengthwise on the saw.

This type of saw is driven by an electric motor that has a belt and pulley. And it lets you easily make adjustments and change the speed.

Vertical

Vertical band saws, also called contour saws, are very versatile.

You can use them for filing, polishing, and contours. They’re also great for all simple stock piece cutting.

Vertical band saws are just as the name suggests, they are vertical machines that are usually driven by an electric motor with belt transmission.

You use this saw by moving your wood against the blade. This machine allows you to manipulate the wood in different ways, including at various angles.

The belt on these machines allows you to adjust the speed.

The loop blade works by rotating between the idler wheel, which is mounted above the worktable, and the drive wheel, which is located under the worktable.

Benchtop

This type of band saw is extremely popular with woodworking hobbyists.

The great thing about benchtop band saws is that they are more mobile than floor standing machines.

They also cost a lot less than floor standing saws. They are designed to be attached to a flat solid surface. This surface will serve as a stable base for the machine.

Believe it or not, benchtop band saws can be just as versatile and powerful as large floor standing units.

And it’s a bonus that they are more portable. They also don’t take up much space.

Floor standing

These are the most expensive type of band saw. They are ideal for contractors and professionals who have commercial cutting needs.

However, they are a bit much for home use. Most hobbyists go with smaller benchtop units.

Floor standing saws are extremely powerful, and they are capable of cutting significant sizes.

Beyond the power and size benefits, another major advantage with this type of saw is that it offers a larger workspace, positioning, and table size.

If you want to make some intricate cuts or rip large pieces, then you will find it much easier with a floor standing saw.

Portable/handheld

Portable and handheld band saws are very different from other band saws.

But because of the way that the blade moves, they have still considered band saws.

Portable band saws have a small cutting area and are about the same size as handheld circular saws. They are mainly used for job-site work.

Handheld machines are especially useful for plumbers who use them to trim pipe.

Some builders and contractors also use them for cutting small workpieces. It’s not unusual for these types of saws to be used on metal or plastic.

Meat

And finally, there are meat band saws. These are used by butchers to trim down and cut large pieces of meat.

There are many affordable meat saws on the market, even floor standing machines. They are ideal for hunters who like to cut their own game after hunting.

Meat band saws were designed to cut through flesh, fat, and bone with very little waste. They look similar to regular floor standing band saws, but they use a special blade made just for meat.

One thing to note with meat band saws is that they are not meant to cut any material other than meat.

The Woodworkers Guild of America has some more excellent information about band saws in this short video.

The Blades of a Band Saw

You can find many different types and sizes of a band saw blades on the market. Each of them is for different uses.

Bandsaw blades are identified by the number of teeth per inch, the thickness or gauge of the blade, and the width.

Generally, the narrower the blade, the tighter the curves you can cut.

And just like with most saws, blades with smaller teeth are best for cutting metal. If you want to cut wood, you will use a blade with larger and fewer teeth.

Most bandsaw blades are between 1/8 and 1/2 inch wide. But you can find larger blades for larger band saws.

How you intend to use the saw will determine the configuration, shape, and spacing of the teeth. Now let’s go over the most common tooth patterns.

Tooth patterns

- Hook tooth blades: The teeth on these blades are spaced more closely than the others. You would use this type of blade if you wanted to cut hardwoods, plastics, and hard non-ferrous metals.

- Skip tooth blades: The teeth on these blades are widely spaced. They are suitable for cutting softer materials like aluminum.

- Wavy and raker-set tooth blades: These blades are most often used for cutting ferrous metal. Wavy-set blades are made for horizontal band saws.

- Toothless blades: You will use this type of blade if you want to cut more fragile pieces. They work great on ceramics and plastics. And they produce a very smooth cut.

To learn more about choosing the right band saw blade for your project, watch this short video.

Recommended Post: Can bandsaw blades be repaired? Find out if it really needs replacement!

Things You Can Do with a Band Saw

As we’ve been discussing, band saws are super versatile. They can handle intricate cuts easily.

You can also use them to size down larger pieces of wood. Here are some of the most common uses for band saws.

Woodwork

Band saws are incredibly versatile for working with wood. And the more you cut with them, the better you’ll get at your craft.

Woodworking is the most common use for band saws. You can do some amazing things with wood with this machine.

Band saws usually come with the angle, fences, and table. These things will allow you to make crosscuts, straight cuts, miter cuts, and a wide range of freehand cuts.

Band saws let you use wood in many different ways. For one, if you have a large piece of wood, you would first use the band saw to cut it down to more manageable chunks.

Then you would use the saw again to get the exact size that you want. From there, you can use the machine to make curved cuts.

Ripping

When the band saw was first invented, it was intended to be used for ripping lumber. People still use it for that reason.

Ripping means cutting down large pieces of wood along the grain. When you rip the wood, you cut down a sizeable unworkable piece of lumber into smaller, more functional pieces.

The cutting capacity and large table size on a band saw make it simple to line up various pieces in a row.

You can then run those pieces along a miter guide or fence to quickly turn them into even smaller pieces.

One example of this is to use the band saw to cut down a big piece of lumber into fence pieces all the same size.

Cutting metal

As I’ve said, you can also use band saws to cut metals. They’re accurate and useful for it.

Intricate detailed cuts are indeed more difficult when you’re cutting metal, but if you’re careful, you can do it.

You can cut many different metal materials with a band saw.

Believe it or not, you can usually use the same saw to cut both metal and wood. You just need to use an appropriate blade.

Resawing

Resawing is another thing that you can do with a band saw. It means sawing a piece of wood along its width.

Using the saw this way turns the wood into two book-matched pieces. This feature is helpful when you’re trying to make things like matching cabinet doors.

You can also use resawing to turn thicker boards into thinner pieces of wood.

This video will show you more about resawing.

Resetting the edge of a board

When you get a piece of wood from the mill, it comes with cut edges. But sometimes it’s better to recut them.

You can even cut several boards at one time. Recutting the edges will ensure that they fit together perfectly.

You can do this work with a jigsaw, but it’s a whole lot easier with a band saw.

Reset the face

Resetting the face of the board is another thing you can do with a band saw.

Using a band saw allows you to take control of the grain so that you can use it for effects in your new piece.

A band saw can help you to make curved cuts featuring the grain in the wood.

Often this technique is used when making furniture parts, such as scrolling table legs.

Make veneer

Working with a thick veneer is another exciting thing you can do with a band saw.

You saw a board into several thin slices. From there, you can use them as a matched set.

This is helpful if you’re making dresser drawers or curved doors.

If you love the look of veneer, watch this video to see how to make it with a band saw.

Make bent laminations

Another technique you can use is cutting the thin laminates that make up a bent lamination.

You cut the laminates one after the other from a thick piece of wood just like you do with the thicker veneer.

Here’s an easy project that you can try with bent laminations to make a curved cutting board.

Process small logs

You can also use your band saw as a mini-mill, which can process little logs. You can use wood from your backyard for this.

This short video will show you five more incredible things that you can do with a band saw.

**Does bandsaw require a set-up? Learn the right settings properly in this guide here!!!**

The Top 6 Best Band Saws

Our top six picks for the best band saw this year include:

- Jet JWBS-14DXPRO

- Powermatic 1791216K Model PWBS-14CS

- SKIL 3386-01

- WEN 3962

- Rikon 10-305

- Grizzly G0555LX

The fact is, there is no one perfect band saw. They all have their pros and cons.

However, even with their limitations, we found all six of these saws to be extraordinary. Let’s discuss the good and bad of each saw.

1. Jet JWBS-14DXPRO

Tap to view on Amazon

If you’re looking for a heavy-duty band saw that could handle professional use and very thick wood, then you should take a look at the Jet JWBS-14DXPRO.

This saw provides increased control and power thanks to the high tension spring design.

It features a cast-iron frame and a unique stand that includes plenty of storage. On top of that, it also comes with an incredible five-year warranty.

The downside to the Jet saw is that it is quite expensive. It’s also too heavy to move around.

If you want a rip fence, you will have to purchase it separately. Another thing that was lacking on this machine is that the tension isn’t even across all blade sizes.

2. Powermatic 1791216K Model PWBS-14CS

Tap to view on Amazon

The Powermatic 1791216K Model PWBS-14CS is another excellent band saw that you should consider.

It’s another heavy-duty machine capable of professional work. It comes with a built-in halogen work lamp.

And the extra-large cast iron worktable is expandable for added stability. This saw does not require any assembly. As the Jet saw, it comes with a five-year warranty.

As great as this saw is, there are a few limitations that you should know about.

First, it’s difficult to make adjustments to this saw. The alignment, expandable worktable, and tensioning belt are all tricky to adjust. This saw is also too heavy to move around.

3. SKIL 3386-01

Tap to view on Amazon

Another band saw worth your time is the SKIL 3386-01. This saw is much smaller than the first two we looked at.

It’s lightweight and easy to move around the shop. We recommend this benchtop machine for beginners. It’s super affordable, and the adjustments are straightforward to make.

This saw also comes with an LED lamp to give you a clear view of your work.

One limitation to this saw is that it is not powerful enough to handle large or professional jobs.

We like that it’s lightweight and portable, but the lighter weight also makes it a bit more unstable than some of the others.

You should also know that this saw only has a one-speed engine with low horsepower.

4. WEN 3962

Tap to view on Amazon

The WEN 3962 is another benchtop band saw that comes with a stand. It offers excellent performance at a low price.

This saw is precise and powerful. It comes with a work light and a stand. And it is ideal for beginners.

One thing worth noting is that the ultrasensitive controls need frequent adjustments.

The initial setup with this machine is also a bit difficult. Another thing that we weren’t crazy about is that you have to remove and adjust the belt to change speeds.

This adjustment isn’t a significant problem, but it is a minor inconvenience.

5. Rikon 10-305

Tap to view on Amazon

If you want one of the best benchtop band saws on the market this year, then you should consider the Rikon 10-305.

The thing that stands out about this saw is the incredible price. You’ll also appreciate the durable cast iron table and the compact size.

Another thing we liked about this saw is that the tracking adjustments are easy to use. It also comes with a five-year warranty.

The downside to this saw is that it doesn’t come with multiple speeds. It also doesn’t come with a stand.

We found that the table tilt can be awkward to adjust too. Also, the machine’s horsepower doesn’t impress us.

6. Grizzly G0555LX

Tap to view on Amazon

The final band saw on our list this year is the Grizzly G0555LX. One of the things that stands out about this machine is the weight.

This is a particularly heavy piece of equipment, weighing 247 pounds. That means that it can handle a lot of pressure.

It has a sturdy cast iron frame. We also really like that it comes with a lower and upper ball bearing blade guide and an adjustable fence with a magnifying window. Another great feature on this saw is the computer balanced cast iron wheels.

We didn’t have too many complaints about this machine. If we could alter anything, it would be to add more horsepower. We’d also like it if the dust port was a little deeper.

A Final Thought

As you can see, band saws are incredibly versatile machines. And you can find them at just about every price point.

Before you purchase a new band saw it’s essential that you decide what you’ll be using the saw for.

That will help you to choose the right machine to meet your individual needs.

We recommend all six of the saws on our list. But our top pick this year is the Grizzly G0555LX.

Tap to view on Amazon

It will do a great job, whether you’re a professional or a home hobbyist. And you can get it without breaking the bank.

Best of luck with your search, and happy woodworking!